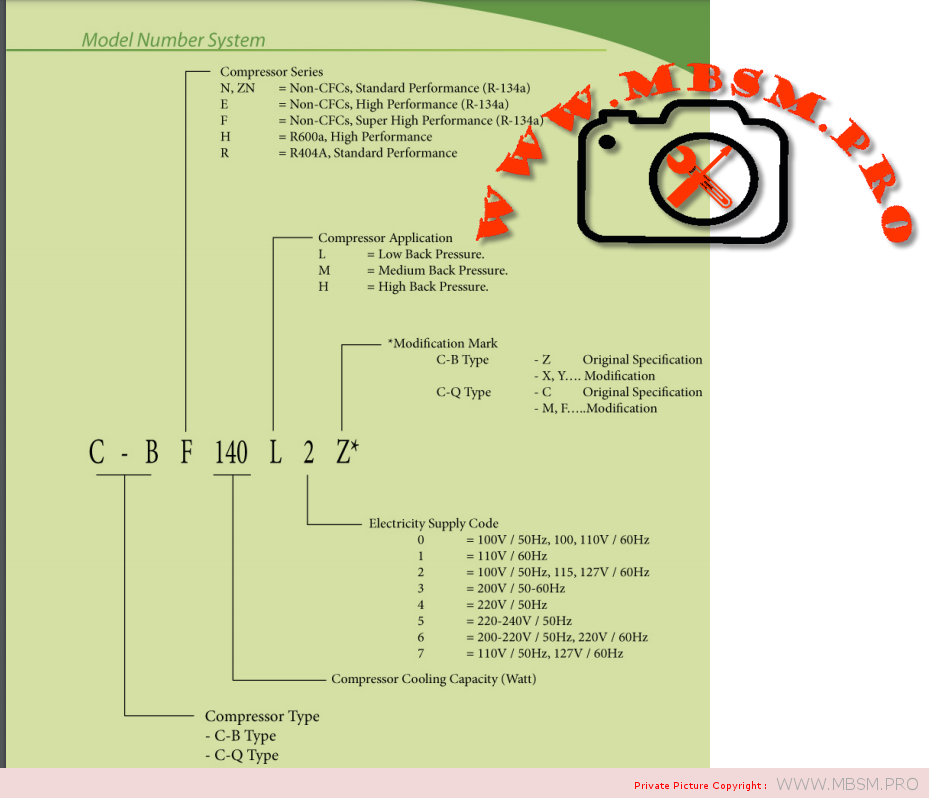

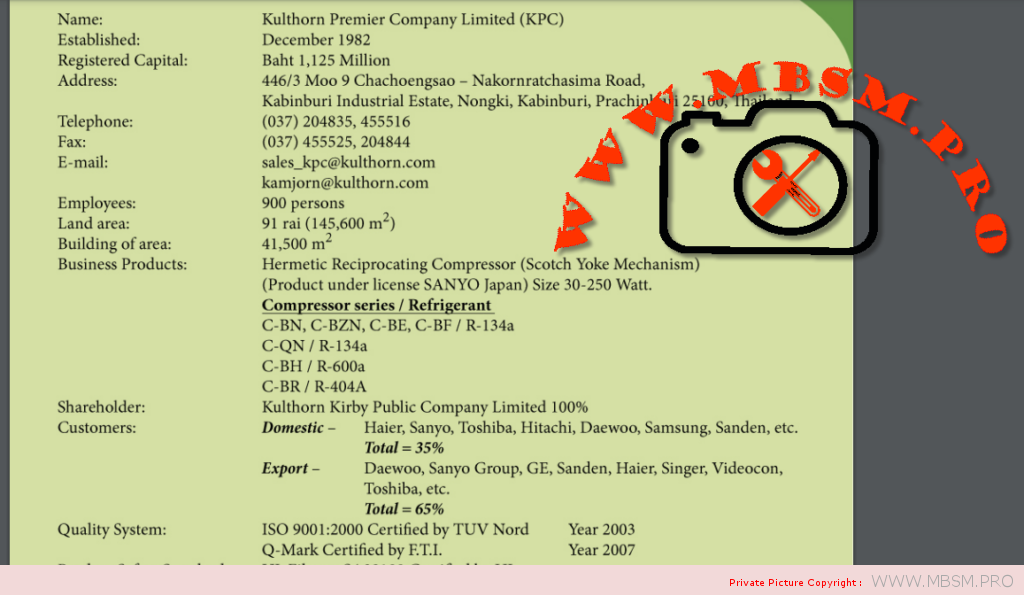

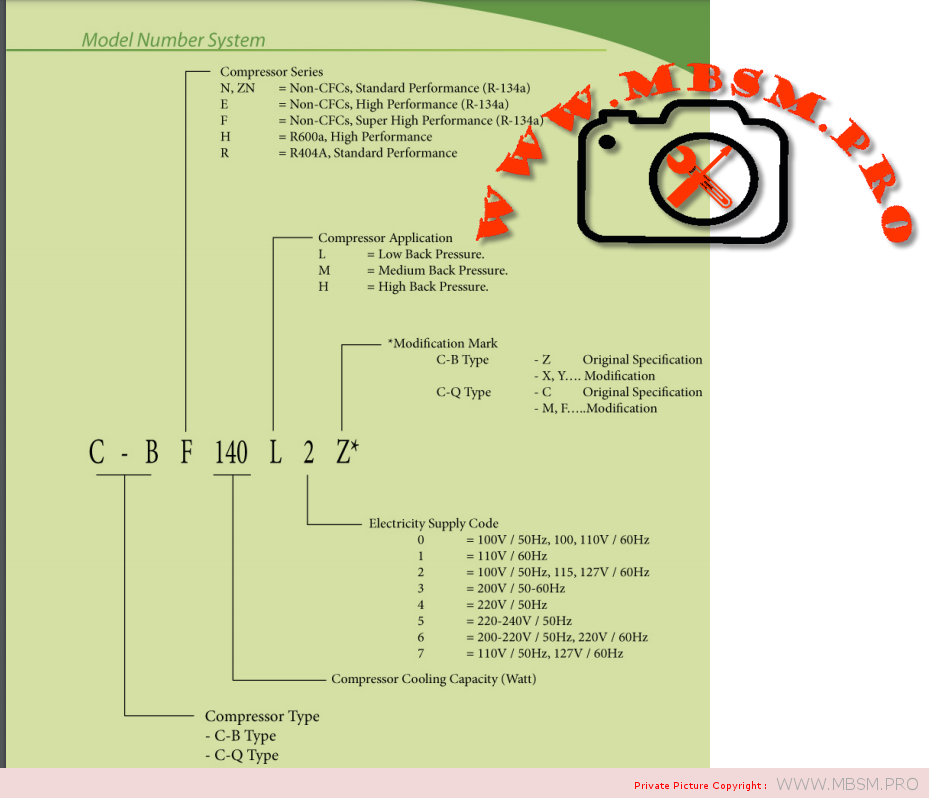

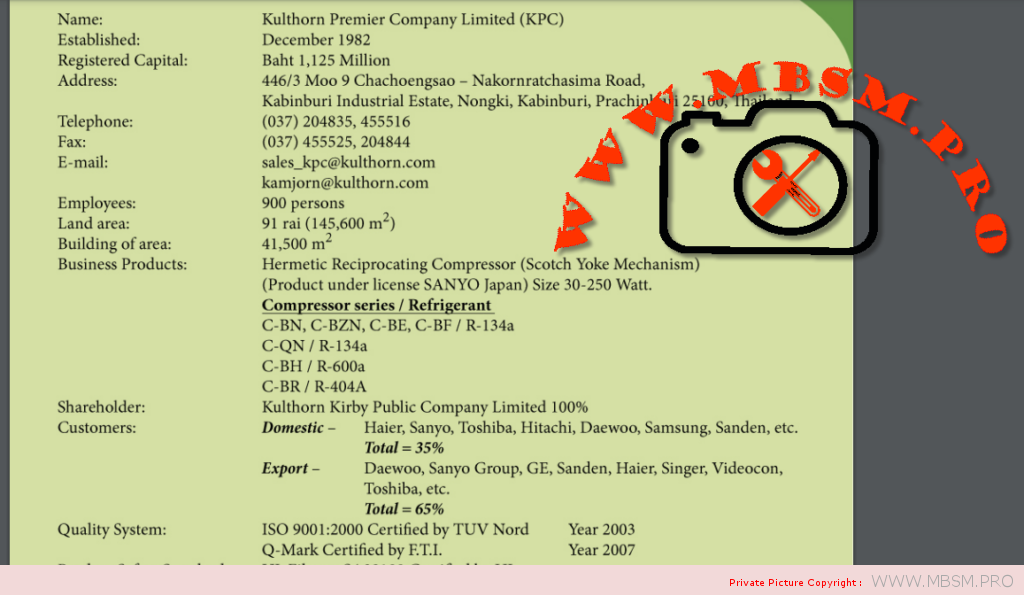

Kulthorn, compressor, Kulthorn compressor, c-qn76l6f, 1/10 Hp, 1Ph, Serie C-q, R134a, 76 watt, Low back pressure, 200-220V/50hz, 220v/60hz, Compressor modefier

Compressor Motor Protectors

Each compressor incorporates a motor protection device or system. Generally, the

larger the compressor, the more sophisticated the motor protector.

It is essential that an electric motor is protected against conditions that could

otherwise result in damage to the motor or to the electrical supply system. For this

reason, every Kulthorn compressor is supplied with a motor protector, sometimes referred

to as an overload. The more expensive the compressor, the greater is the economic

justification for specifying a motor protector that has the ability to protect over a wider

range of conditions.

- External Motor Protectors

A smaller compressor (such as an AZ, AE or WJ) is fitted with an external motor

protector. Most commonly, this is a compact, cylindrical device that contains a snapaction bimetallic disc. The protector is mounted in contact with the surface of the

compressor housing, inside the terminal guard.

The compressor current passes through the bimetallic disc. The resistance of this disc

causes the disc temperature to increase as the motor current increases. There is usually

a small heater, located under the disc and connected in series with the disc itself. This

heater further raises the temperature of the disc. There is also the impact of the

compressor shell temperature, and a hot compressor will further increase the disc

temperature. The temperature of the disc is thus influenced by the combined effects of –

• the compressor motor current

• the compressor shell temperature

When the bimetallic disc reaches a predetermined temperature (often either 105°C or

120°C) the disc will snap open, and power supply to the compressor will be interrupted.

The compressor will cool, and at a reduced disc temperature the protector will reset

and the compressor will restart, or attempt to restart. If the abnormal condition that

caused the protector to trip in the first place still exists, the compressor is likely to continue

to cycle on the overload until that condition is corrected.

There are two situations where a motor protector is expected to operate. - When the compressor is running under extreme conditions.

- When the compressor is in a locked rotor condition. This is a situation where the

compressor cannot start because the voltage is too low, the system pressures are

outside the range for which the compressor is approved, there is internal damage to

the compressor, or there is some other reason why the compressor is incapable of

starting

| Attachment | Type | Link |

|---|---|---|

| Mbsm_dot_pro_private_picture_c-qn76l6f | image/jpeg | Get Link |

| Mbsm_dot_pro_private_picture_c-qn76l6f | image/png | Get Link |

| Mbsm_dot_pro_private_picture_c-qn76l6f-1 | image/png | Get Link |

| Mbsm_dot_pro_private_PDF_2019-06-13_110312_technical_bulletin | application/pdf | Get Link |

| Mbsm_dot_pro_private_PDF_Model-Number-System | application/pdf | Get Link |

| Mbsm_dot_pro_private_PDF_Kulthorn-Catalog | application/pdf | Get Link |

| Mbsm_dot_pro_private_picture_c-qn76l6-1f | image/png | Get Link |

| Mbsm_dot_pro_private_PDF_kpccatalog | application/pdf | Get Link |

| Mbsm_dot_pro_private_PDF_KULTHORN-CATALOGUE_web | application/pdf | Get Link |

| Mbsm_dot_pro_private_picture_c-qn76l6-2f | image/png | Get Link |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

Kulthorn C-BF175L5Z BTU (LOW BACK COMPRESSOR) DETAIL SEND ME