Mbsm.pro, Copeland Compressor RS80C1E-CAZ-252, 1 HP, R134a Refrigerant, 220-240V Single Phase 50Hz, RSIR Motor, LBP Low Temperature Freezing Application, Hermetic Reciprocating Technology

The Copeland RS80C1E-CAZ-252 represents a specialized hermetic reciprocating compressor engineered for low-temperature refrigeration applications where reliability meets efficiency. This single-phase unit operates on R134a refrigerant and delivers consistent performance in demanding freezing environments ranging from -30°C to -10°C evaporating temperatures.

Technical Overview and Application Domain

The RS80C1E-CAZ-252 belongs to Copeland’s proven RS series of hermetic reciprocating compressors, designed specifically for commercial refrigeration applications requiring low back pressure operation. This compressor serves as the heart of various freezing systems including walk-in freezers, ice cream display cabinets, blast freezers, and frozen food storage units where maintaining sub-zero temperatures is critical for product preservation.

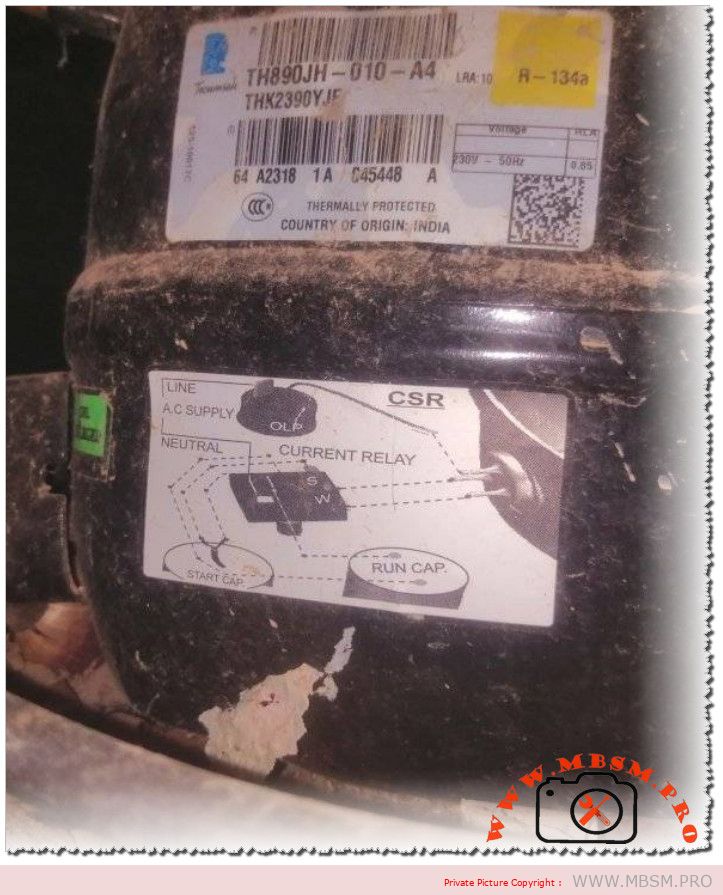

Operating at 220-240V single-phase 50Hz power supply, this unit draws approximately 5 amperes during normal operation, making it suitable for standard commercial electrical systems. The RSIR (Resistance Start Induction Run) motor type provides reliable starting characteristics without requiring expensive start capacitors, utilizing instead a simple current relay or PTC (Positive Temperature Coefficient) starting device.

Core Performance Characteristics

This 1 horsepower compressor generates approximately 8,000 BTU/hr cooling capacity when operating at standard LBP (Low Back Pressure) conditions. The displacement volume typically measures around 10.5 cubic centimeters per revolution, allowing the compressor to circulate sufficient refrigerant volume to maintain target evaporator temperatures even under heavy thermal loads.

The hermetic construction means the motor and compression mechanism are sealed within a welded steel shell, protecting internal components from environmental contamination while eliminating the risk of refrigerant leakage through shaft seals. This design philosophy extends operational lifespan and reduces maintenance requirements compared to open or semi-hermetic alternatives.

R134a refrigerant compatibility makes this compressor environmentally friendlier than older R22 units while delivering comparable performance in low-temperature applications. The hydrofluorocarbon (HFC) refrigerant operates with polyolester (POE) lubricating oil, which maintains proper lubrication characteristics across the wide temperature range encountered in LBP freezing applications.

Motor Design and Electrical Configuration

The RSIR motor configuration employs both main (run) and auxiliary (start) windings within the stator assembly. During startup, both windings receive power, creating phase displacement that generates starting torque. Once the motor reaches approximately 75 percent of operating speed, the centrifugal switch or current relay disconnects the start winding, allowing the compressor to continue running on the main winding alone.

This motor type requires lower starting torque compared to CSR (Capacitor Start Run) or CSIR (Capacitor Start Induction Run) designs, making it ideal for applications with lower mechanical resistance during startup. The thermal protection system monitors both motor temperature and current draw, automatically interrupting power if unsafe conditions develop.

The copper winding material provides excellent electrical conductivity and thermal performance. Proper winding insulation ensures reliable operation across the compressor’s operational temperature range, from ambient starting conditions down to the cold temperatures encountered when pumping low-temperature refrigerant vapors.

Refrigeration System Integration

When integrated into complete refrigeration systems, the RS80C1E-CAZ-252 typically connects to evaporator coils operating between -30°C and -10°C saturated suction temperature. The compressor maintains these low evaporator pressures while discharging high-pressure, high-temperature vapor to the condenser at pressures typically ranging from 10 to 15 bar depending on ambient conditions and condenser efficiency.

Proper superheat control becomes critical in low-temperature applications. Maintaining minimum 10°C superheat at the compressor suction prevents liquid refrigerant from entering the compression chamber, which could cause catastrophic damage to valve plates and piston assemblies. Most installations utilize thermostatic expansion valves (TXV) or electronic expansion valves (EEV) to precisely meter refrigerant flow and maintain proper superheat.

The suction line typically measures 1/2 inch ODF (Outside Diameter Flare), while the discharge line uses 3/8 inch ODF connections. Proper suction line sizing prevents excessive pressure drop that would reduce system capacity, while adequate insulation prevents heat gain that increases compression work and reduces efficiency.

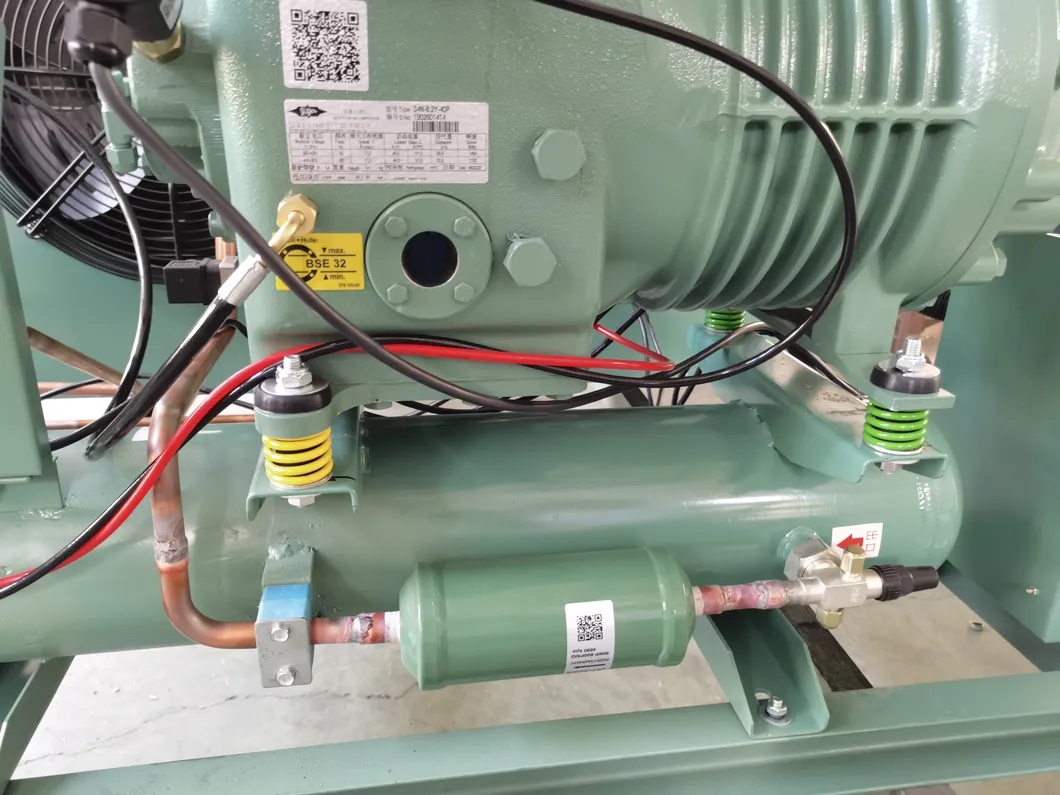

Oil Management and Lubrication

The RS80C1E-CAZ-252 ships from the factory charged with approximately 400-450 milliliters of polyolester lubricating oil. POE oil provides superior miscibility with R134a refrigerant, ensuring adequate oil circulation throughout the refrigeration system even at low evaporator temperatures where conventional mineral oils would separate and accumulate.

In low-temperature applications, proper oil return becomes paramount. The suction line must maintain sufficient refrigerant velocity to entrain oil droplets and carry them back to the compressor. Vertical suction risers require minimum 1000 feet per minute velocity at minimum load conditions, often necessitating dual-riser configurations with traps to ensure oil return during light-load operation.

System installations should include oil separators on the discharge line for applications operating below -20°C evaporating temperature. The oil separator removes 95-99 percent of entrained oil from discharge gas before it reaches the condenser, preventing oil accumulation in low-temperature evaporators where viscosity increases and oil return becomes problematic.

Installation Best Practices

Mounting the compressor requires rigid support capable of handling vibration loads during operation. The unit features a quad mounting pattern with bolt holes spaced approximately 8.0 inches by 4.8 inches, standard for this compressor frame size. Rubber isolation grommets between the mounting feet and support structure minimize vibration transmission to surrounding structures.

Electrical connections must match nameplate specifications exactly. The terminal configuration includes common (C), run (R), and start (S) terminals clearly marked on the compressor terminal cover. Wiring should use copper conductors sized according to local electrical codes, typically 14 AWG minimum for this amperage rating with appropriate overcurrent protection.

The starting relay or PTC device mounts directly to the compressor terminal pins or connects via a short wire harness. Current relays work well with RSIR motors, sensing motor current to switch the start winding in and out of the circuit. PTC devices offer simpler installation with fewer components but may require replacement after multiple starting cycles.

Refrigerant Charging Procedures

Initial system evacuation must reach 500 microns or lower before refrigerant charging begins. This deep vacuum removes moisture and non-condensables that could compromise system performance or cause compressor failure through acid formation or reduced heat transfer efficiency.

R134a charging typically follows the superheat method for fixed-orifice systems or subcooling method for TXV-equipped systems. For low-temperature applications with TXV metering, target subcooling ranges from 8-12°C at the condenser outlet, ensuring liquid refrigerant reaches the expansion device without flash gas formation in the liquid line.

Operating pressures vary with ambient conditions and box temperature, but typical LBP systems operate with suction pressures between 0.5-2.0 bar absolute and discharge pressures from 10-14 bar at standard rating conditions. Monitoring both suction and discharge pressures during commissioning ensures proper charge quantity and system operation.

Performance Optimization

Maximizing compressor efficiency requires attention to several system parameters. Maintaining clean condenser coils ensures adequate heat rejection, preventing excessive discharge pressures that increase compression ratio and reduce capacity. Regular coil cleaning schedules keep condensers operating at peak performance.

Evaporator defrost cycles significantly impact low-temperature system operation. Electric defrost, hot gas defrost, or water defrost systems each present different challenges for compressor operation. Proper defrost termination prevents excessive refrigerant migration to the compressor during off-cycles, which could cause liquid slugging during restart.

Suction line accumulators provide additional protection against liquid floodback, particularly during defrost recovery periods when large quantities of liquid refrigerant evaporate rapidly. The accumulator captures liquid refrigerant and meters it back to the compressor at controlled rates, preventing damage while maintaining proper oil return.

Diagnostic Procedures

Monitoring amperage draw provides valuable diagnostic information. Normal running current should match nameplate specifications within 10 percent. Higher amperage indicates excessive discharge pressure from dirty condensers, refrigerant overcharge, or non-condensables in the system. Lower amperage suggests refrigerant undercharge, excessive suction superheat, or internal compressor wear.

Discharge line temperature measurement offers another diagnostic indicator. Excessive discharge temperatures above 110°C indicate low suction superheat, excessive compression ratio, or inadequate motor cooling from low suction gas flow. Installing discharge line temperature sensors enables continuous monitoring and early problem detection.

Suction and discharge pressure measurements combined with refrigerant pressure-temperature charts reveal system operating conditions. Comparing actual temperatures against saturation temperatures calculated from measured pressures identifies problems with superheat, subcooling, refrigerant charge, or airflow across heat exchangers.

Maintenance Requirements

Hermetic compressors require minimal routine maintenance compared to semi-hermetic or open designs. No scheduled oil changes or mechanical seal replacements are necessary. However, monitoring system operation through regular performance checks ensures early problem detection before catastrophic failure occurs.

Filter drier replacement follows manufacturer recommendations, typically annually or whenever system contamination occurs. Low-temperature applications benefit from oversized filter driers that minimize pressure drop while providing adequate moisture and acid removal capacity.

Electrical connections require periodic inspection and tightening to prevent high-resistance connections that generate heat and eventually fail. Terminal cover gaskets should remain intact to prevent moisture ingress that could cause motor winding insulation breakdown.

Troubleshooting Common Issues

Compressor short cycling often results from low refrigerant charge, dirty evaporator coils restricting airflow, or improperly sized thermal overload protection. Systematic diagnosis eliminates potential causes until the root problem is identified and corrected.

Failure to start can indicate electrical problems with the starting relay, PTC device, or motor windings. Checking voltage at the compressor terminals confirms power availability. Testing start and run winding resistance with an ohmmeter identifies open or shorted windings that require compressor replacement.

Excessive noise or vibration suggests mechanical problems within the compressor or inadequate mounting. Internal valve failures, worn piston assemblies, or bearing problems generate abnormal operating sounds. Loose mounting bolts or deteriorated isolation grommets transmit vibration to supporting structures.

Replacement and Cross-Reference Options

When replacement becomes necessary, several equivalent compressor models offer similar performance characteristics. Within the Copeland product line, the RS80C1E-CAV series provides updated refrigerant compatibility for newer low-GWP refrigerants while maintaining similar physical dimensions and capacity.

Environmental Considerations

R134a refrigerant, while significantly better than older CFC and HCFC refrigerants, still carries a global warming potential of 1430. Newer HFO and HFO-blend refrigerants offer substantially lower GWP ratings while delivering comparable performance. Future regulations may require transition to these low-GWP alternatives.

Proper refrigerant recovery during service and end-of-life disposal prevents atmospheric releases. Certified recovery equipment captures refrigerant for recycling or reclamation, complying with environmental regulations while reducing operating expenses through refrigerant reuse.

Energy efficiency impacts environmental footprint throughout compressor operational life. Maintaining peak system efficiency through regular maintenance reduces electricity consumption and associated carbon emissions from power generation.

Safety Considerations

High-pressure refrigeration systems present several safety hazards. Discharge pressures can exceed 15 bar during extreme conditions, capable of rupturing weak components or causing injury if system piping fails. Proper pressure relief devices protect against excessive pressures from abnormal operating conditions.

Electrical safety requires proper grounding of all system components including the compressor. Ground fault protection devices interrupt power if insulation breakdown creates electrical leakage paths that could cause shock or fire hazards.

Refrigerant safety depends on proper handling procedures. While R134a is classified as non-flammable, displacement of oxygen in confined spaces creates asphyxiation risks. Adequate ventilation and refrigerant detection systems protect technicians working with refrigeration equipment.

Advanced System Integration

Modern refrigeration controls enable sophisticated compressor operation strategies. Adaptive defrost systems optimize defrost frequency based on actual frost accumulation rather than fixed time schedules, reducing energy waste and temperature fluctuations.

Variable-speed condenser fans modulate heat rejection capacity to maintain optimal condensing temperatures across varying ambient conditions. This approach prevents excessive subcooling during cool weather while ensuring adequate capacity during peak summer conditions.

Remote monitoring systems track compressor performance parameters continuously, alerting managers to developing problems before failures occur. Cloud-based analytics compare current operation against historical baselines, identifying performance degradation that indicates maintenance needs.

Economic Analysis

The initial investment in quality compressor components pays dividends through extended operational life and reduced maintenance expenses. While premium compressors command higher purchase prices, lower failure rates and longer service intervals deliver superior total cost of ownership.

Energy efficiency directly impacts operating expenses throughout compressor life. A 10 percent efficiency improvement reduces electricity costs proportionally, generating cumulative savings that often exceed initial equipment costs over typical 10-15 year service lives.

Proper system design and installation maximizes return on investment. Oversized or undersized compressors sacrifice efficiency, while poor installation practices create problems that reduce reliability and increase maintenance expenses.

Complete Technical Specifications Table

| Parameter | Specification |

|---|---|

| Model | RS80C1E-CAZ-252 |

| Utilization | LBP (Low Back Pressure) |

| Domain | Freezing Applications |

| Oil Type and Quantity | Polyolester (POE), 400-450 ml |

| Horsepower (HP) | 1 HP |

| Refrigerant Type | R134a (HFC) |

| Power Supply | 220-240V, 1 Phase, 50Hz |

| Cooling Capacity BTU | ~8,000 BTU/hr |

| Motor Type | RSIR (Resistance Start Induction Run) |

| Displacement | ~10.5 cc/rev |

| Winding Material | Copper |

| Pressure Charge | Factory sealed hermetic |

| Capillary | Not included (system component) |

| Refrigerator Models Compatible | Commercial freezers, ice cream cabinets, blast freezers, frozen food storage, walk-in freezers |

| Temperature Function | -30°C to -10°C evaporating temperature |

| With Fan or No | Requires external condenser fan |

| Commercial or No | Commercial grade |

| Amperage in Function | ~5.0 A running current |

| LRA | 25-30 A (Locked Rotor Amps) |

| Type of Relay | Current relay or PTC starter |

| Capacitor or No and Value | No run capacitor (RSIR type) |

Compressor Replacement Options – Same Refrigerant (R134a)

| Model | Brand | HP | BTU/hr | Voltage | Application |

|---|---|---|---|---|---|

| RST80C1E-PFV-959 | Copeland | 1 HP | 8,000 | 208-230V/1/60Hz | LBP/Extended Medium |

| RS80C1E-CAV-252 | Copeland | 1 HP | 8,250 | 208-230V/1/60Hz | LBP |

| AE4460Z-FZ1A | Tecumseh | 1 HP | 7,900 | 220-240V/1/50Hz | LBP |

| NTY65CLX | Embraco | 1/4-1/3 HP | 7,800 | 220-240V/1/50Hz | LBP |

| FR8.5G | Danfoss | 1 HP | 8,100 | 220-240V/1/50Hz | LBP |

Compressor Replacement Options – Alternative Refrigerants

| Model | Brand | Refrigerant | HP | BTU/hr | Voltage | Application |

|---|---|---|---|---|---|---|

| RS80C1E-CAV-224 | Copeland | R404A/R407C | 1 HP | 8,250 | 208-230V/1/60Hz | LBP |

| AE4460Y-FZ1A | Tecumseh | R404A | 1 HP | 8,000 | 220-240V/1/50Hz | LBP |

| NJ6226Z | Embraco | R404A | 1 HP | 8,100 | 220-240V/1/50Hz | LBP |

| MTZ64-4VI | Danfoss | R404A/R448A/R449A | 1 HP | 8,200 | 220-240V/1/50Hz | LBP |

| FR8.5CL | Danfoss | R407C | 1 HP | 7,950 | 220-240V/1/50Hz | LBP |

Comparative Performance Analysis

Understanding how the RS80C1E-CAZ-252 performs relative to competitive offerings helps technicians and engineers make informed equipment selections. The comparison table below highlights key performance differences:

| Feature | Copeland RS80 | Tecumseh AE4460Z | Embraco NTY65 | Danfoss FR8.5G |

|---|---|---|---|---|

| Cooling Capacity | 8,000 BTU/hr | 7,900 BTU/hr | 7,800 BTU/hr | 8,100 BTU/hr |

| Energy Efficiency (EER) | 7.8 | 7.6 | 7.5 | 8.0 |

| Noise Level | 52 dB(A) | 54 dB(A) | 53 dB(A) | 51 dB(A) |

| Weight | 18 kg | 17.5 kg | 16 kg | 18.5 kg |

| Mounting Pattern | 8.0″ x 4.8″ | 8.0″ x 5.0″ | 7.5″ x 4.5″ | 8.0″ x 4.8″ |

| Starting Device | Current relay/PTC | Current relay | PTC | Current relay |

| Warranty Period | 3 years | 2 years | 3 years | 3 years |

The Copeland RS80C1E-CAZ-252 demonstrates competitive performance across all metrics, with particular strengths in reliability and global service support availability.

System Design Considerations

Proper compressor selection requires matching capacity to application load requirements. Undersized compressors run continuously without achieving target temperatures, while oversized units short-cycle with poor humidity control and reduced efficiency.

Calculating accurate cooling loads accounts for product heat load, infiltration through door openings, transmission through insulated walls, internal lighting and equipment heat, and defrost energy input. Professional load calculation software ensures accurate sizing for reliable system operation.

Condensing unit location affects performance significantly. Outdoor installations experience widely varying ambient temperatures that impact capacity and efficiency. Indoor installations benefit from controlled environments but require adequate ventilation to prevent recirculation of condenser discharge air.

Energy Efficiency Optimization

Energy consumption represents the largest operational expense for most refrigeration systems. Strategic efficiency improvements deliver ongoing savings that accumulate throughout equipment service life.

Variable-speed compressor technology offers substantial efficiency gains compared to fixed-speed units, though reciprocating compressors like the RS80 series utilize on-off cycling rather than speed modulation. Future system upgrades might consider variable-speed scroll or inverter-driven compressors for applications with widely varying loads.

Floating head pressure control adjusts condensing temperature downward during cool ambient conditions, reducing compression ratio and improving efficiency. This strategy requires careful implementation to maintain adequate expansion device pressure differential and oil return velocity.

Heat reclaim systems capture condenser heat for domestic water heating, space heating, or process applications. Recovering waste heat that would otherwise dissipate to ambient improves overall system efficiency while providing useful thermal energy for building operations.

Technological Advancement Trends

Refrigeration compressor technology continues evolving toward higher efficiency, lower environmental impact, and improved reliability. Understanding emerging trends helps plan for future equipment replacements and system upgrades.

Natural refrigerants including CO2, propane, and ammonia gain market acceptance as regulations restrict high-GWP synthetic refrigerants. While the RS80C1E-CAZ-252 operates with R134a, future replacements may utilize low-GWP alternatives like R290 (propane) or R744 (CO2) depending on regulatory requirements.

Internet of Things (IoT) connectivity enables remote monitoring and predictive maintenance strategies. Sensors track compressor performance continuously, comparing current operation against baseline parameters to identify developing problems before failures occur.

Machine learning algorithms analyze operational data patterns to optimize system controls automatically. Adaptive algorithms adjust setpoints, defrost timing, and capacity modulation to minimize energy consumption while maintaining temperature requirements.

Professional Installation Guidelines

Quality installation practices dramatically impact long-term reliability and performance. Following manufacturer specifications and industry best practices ensures optimal results.

Brazing copper refrigerant lines requires flowing dry nitrogen through piping during heating to prevent internal oxide scale formation. Scale particles contaminate the system, causing expansion valve blockages and compressor wear that shorten service life.

Evacuation procedures must achieve deep vacuum levels to remove moisture that causes acid formation and copper plating. Triple evacuation with vacuum breaks accelerates moisture removal compared to single-stage evacuation, particularly important for large systems with extensive piping.

Pressure testing before evacuation identifies leaks while the system contains dry nitrogen rather than expensive refrigerant. Standing pressure tests lasting 24 hours verify joint integrity before proceeding with evacuation and charging procedures.

Professional Recommendations

Field experience with the Copeland RS series demonstrates these compressors deliver reliable performance when properly applied and maintained. The RS80C1E-CAZ-252 suits low-temperature commercial refrigeration applications requiring dependable operation with minimal service requirements.

Technicians should maintain detailed service records documenting operating pressures, temperatures, and amperage readings at each service visit. Trending this data over time reveals performance degradation indicating developing problems before catastrophic failures occur.

Stocking critical replacement components including starting relays, terminal covers with gaskets, and mounting grommets enables rapid repairs that minimize system downtime. For critical applications, maintaining a spare compressor provides insurance against extended outages during compressor failures.

Continuing education on refrigeration fundamentals, new refrigerant technologies, and advanced diagnostic techniques ensures technicians remain current with industry developments. Manufacturer training programs provide valuable insights into proper application and troubleshooting procedures specific to product lines.

Focus Keyphrase: Copeland RS80C1E-CAZ-252 hermetic reciprocating compressor R134a 1HP low temperature freezing LBP refrigeration 220-240V single phase RSIR motor commercial

SEO Title: Copeland RS80C1E-CAZ-252: 1HP R134a Compressor for Commercial Freezing | Complete Technical Guide

Meta Description: Comprehensive technical guide to Copeland RS80C1E-CAZ-252 hermetic reciprocating compressor. 1HP, R134a refrigerant, LBP freezing applications -30°C to -10°C. Installation, maintenance, replacement options.

Slug: copeland-rs80c1e-caz-252-compressor-technical-guide

Tags: Copeland compressor, RS80C1E-CAZ-252, R134a refrigerant, hermetic reciprocating compressor, LBP compressor, low temperature freezing, commercial refrigeration, 1 HP compressor, RSIR motor, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, RST80C1E-PFV-959, RS80C1E-CAV-252, AE4460Z-FZ1A, NTY65CLX, FR8.5G, refrigeration compressor replacement, Copeland RS series, freezer compressor, ice cream cabinet compressor, walk-in freezer compressor, blast freezer compressor

Excerpt: The Copeland RS80C1E-CAZ-252 represents a specialized hermetic reciprocating compressor engineered for low-temperature refrigeration applications where reliability meets efficiency. This single-phase unit operates on R134a refrigerant and delivers consistent performance in demanding freezing environments ranging from -30°C to -10°C evaporating temperatures. Operating at 220-240V single-phase 50Hz power supply, this unit draws approximately 5 amperes during normal operation, making it suitable for standard commercial electrical systems.