Technical data

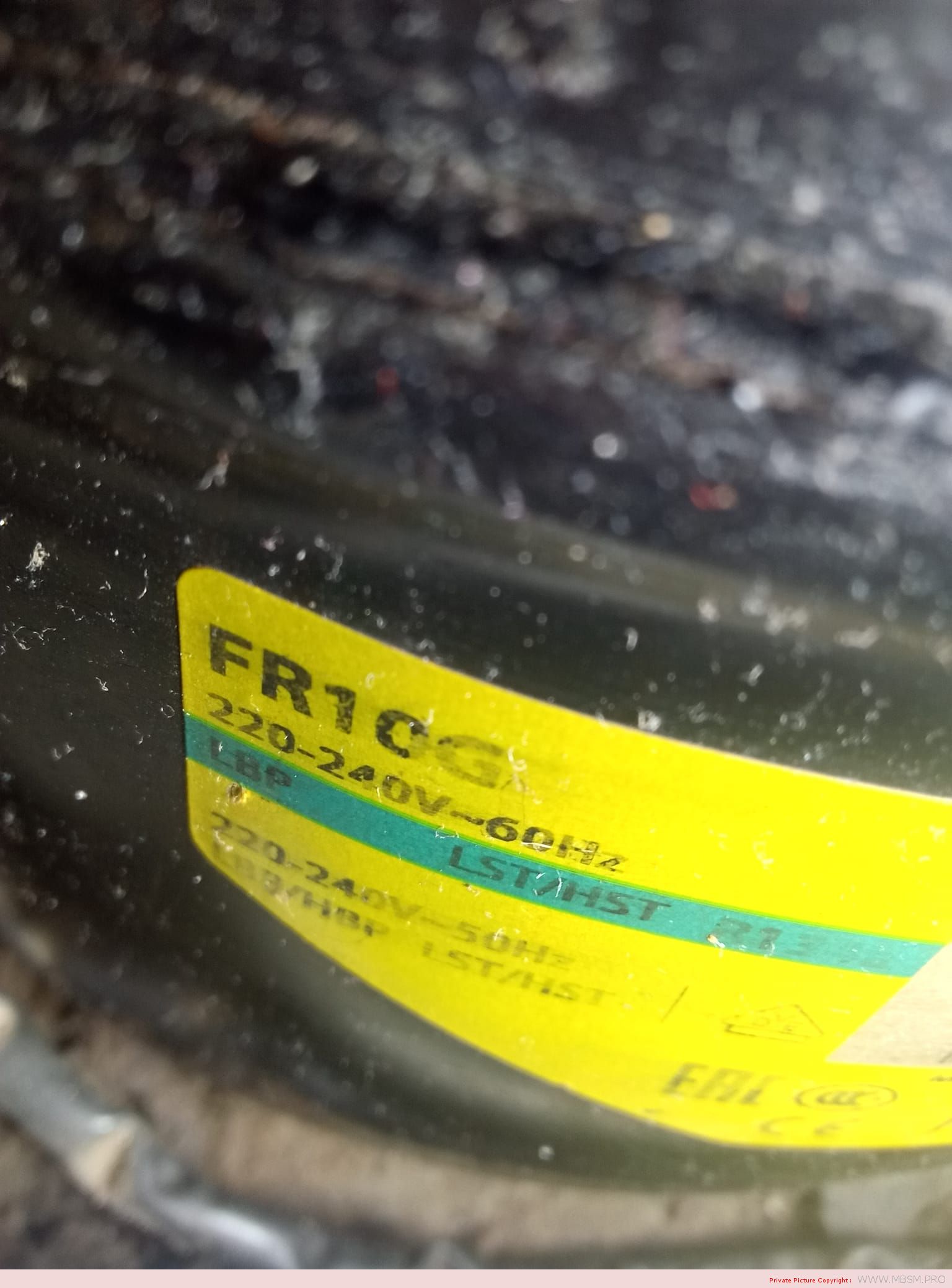

- Model: FR10G

- Refrigerant Gas: R-134a

- Pression/temperature: MHBP

- Power: 1/4 HP

- Frequency: 50/60 Hz

- Compressor Type: Hermetic

- Displacement: 9.05 cm³

- Power Cons. -25°C: 179 W

- Power Cons. -10°C: 265 W

- Power Cons. -5°C: 296 W

- Efficiency 0°C: 329 W

- Power Cons. +5°C: 362 W

- Power Cons. +7,2°C: 376 W

- T° Condensation: 55 °C

- Cooling Cap. -30°C: 97 Kcal/h

- Cooling Cap. -25°C: 144 Kcal/h

- Cooling Cap. -20°C: 199 Kcal/h

- Cooling Cap. -15°C: 265 Kcal/h

- Cooling Cap. -10°C: 344 Kcal/h

- Cooling Cap. -5°C: 439 Kcal/h

- Cooling Cap. 0°C: 549 Kcal/h

- Cooling Cap. 5°C: 680 Kcal/h

- Cooling Cap. 7.2°C: 745 Kcal/h

- Cooling Cap. 10°C: 832 Kcal/h

- Test Type: Ashare 32

Specs

| Attachment | Type | Link |

|---|---|---|

| Mbsm_dot_pro_private_picture_FR10G | image/jpeg | Get Link |

| Mbsm_dot_pro_private_PDF_FR10G | application/pdf | Get Link |

| Image | View Image |

On this model what is it psi applicable? For undercounter chiller refrigerator I’m newly tech.from Philippines’

Thank you.

For the Copeland RS80C1E-CAZ-252 compressor mentioned in that model specification, here are the applicable operating pressures (PSI) for an undercounter unit using R134a refrigerant:

1. Suction Pressure (Low Side)

Since this is a Low Back Pressure (LBP) compressor designed for evaporating temperatures between -30°C and -10°C, the suction pressure will be relatively low.

For Freezer Applications: 0 to 5 PSI.

For Chiller/Refrigerator Applications: 10 to 15 PSI.

Target: For an undercounter chiller, you should typically aim for 12 to 15 PSI once the unit has reached its operating temperature.

2. Discharge Pressure (High Side)

This depends heavily on the ambient temperature. In a tropical climate like the Philippines, the high-side pressure will be on the higher end of the scale.

Normal Range: 150 to 185 PSI.

High Ambient/Hot Day: 190 to 215 PSI.

Conversion Note: The technical data for this model lists discharge pressures between 10 and 15 bar, which equals roughly 145 to 217 PSI.

Technical Tips for a New Tech:

Superheat: Aim for a suction superheat of about 10°C (18°F) at the compressor inlet to ensure no liquid refrigerant returns to the compressor, which can damage the valves.

Oil: This model uses POE (Polyolester) oil. If you are doing a repair, avoid leaving the system open to the air for long, as POE oil absorbs moisture very quickly.

Charging: Always charge by weight according to the nameplate on the undercounter unit if possible. If charging by pressure, let the unit run for at least 20–30 minutes before making final adjustments to the PSI.

This compressor is a 1 HP unit, so it is quite powerful for an undercounter system; ensure the condenser is clean to keep that discharge pressure within the safe 150–200 PSI range.