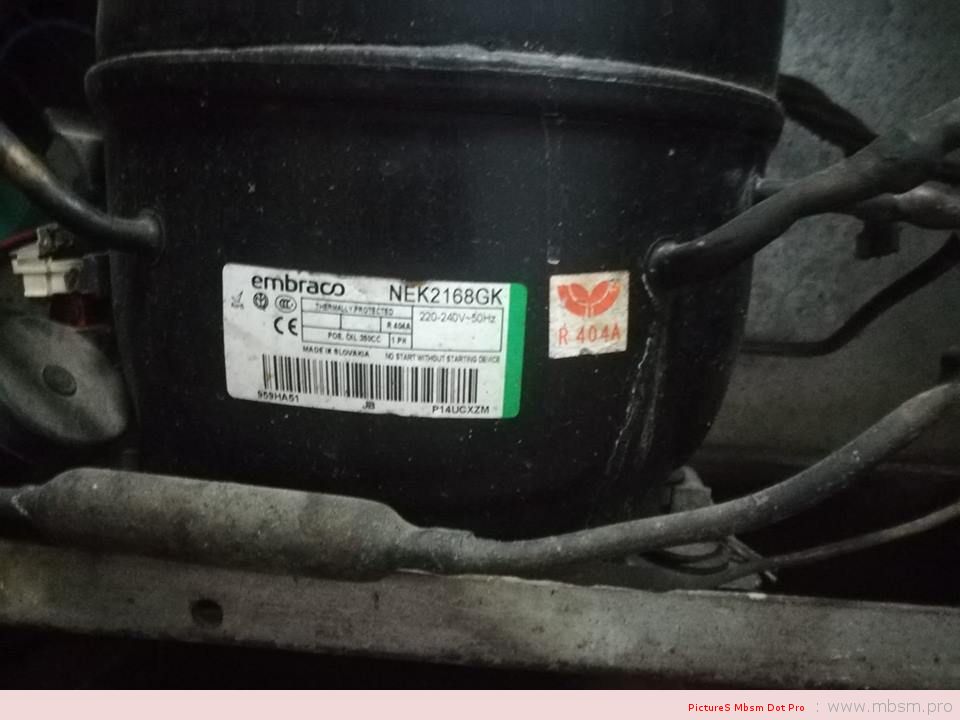

Mbsm.pro, Compressor, GM70AZ, 1/5 hp, ZMC, Cooling, R134a, 150 W, 1.3 A, 1Ph 220‑240V 50Hz, LBP capacity, RSIR, −30°C to −10°C

Le compresseur hermétique ZMC GM70AZ, visible sur l’étiquette de la photo, est un modèle fonctionnant au réfrigérant R134a, conçu pour les applications à basse pression d’aspiration dans le froid ménager. Fabriqué en Égypte par Misr Compressor Manufacturing Co. (ZMC), il cible les réfrigérateurs et congélateurs domestiques alimentés en 220–240 V, 50 Hz, très répandus en Afrique du Nord et au Moyen‑Orient.

Caractéristiques techniques essentielles

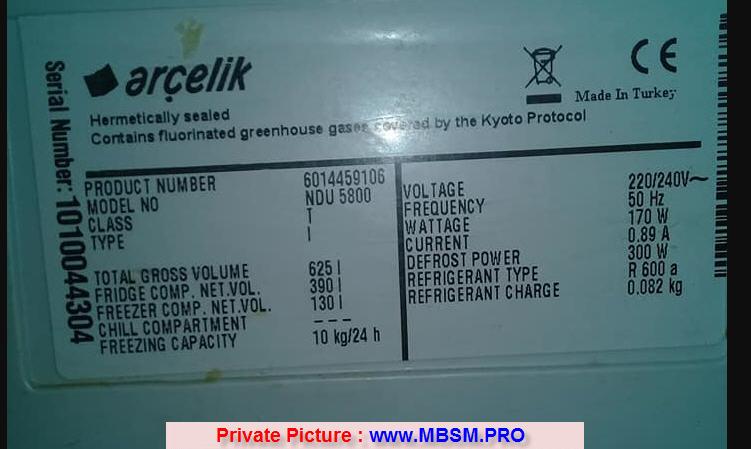

Le GM70AZ appartient à la famille de compresseurs LBP (Low Back Pressure), avec une plage d’évaporation typique d’environ −30 °C à −10 °C adaptée au froid négatif. Il fonctionne au réfrigérant R134a, avec un refroidissement du moteur par convection statique et une alimentation monophasée 220–240 V, 50 Hz comme indiqué sur l’étiquette.

Ce compresseur offre une puissance de l’ordre de 1/5 HP, ce qui le positionne pour des réfrigérateurs et congélateurs ménagers de petite à moyenne capacité. Il est fourni avec des connexions brasées pour aspiration, refoulement et process, ce qui facilite son intégration dans les circuits frigorifiques standards des fabricants et des ateliers de maintenance.

Tableau – Données techniques typiques ZMC E/GM70AZ

| Paramètre | Valeur indicative |

|---|---|

| Modèle | GM70AZ / EGM70AZ |

| Réfrigérant | R134a |

| Application | LBP (basse pression d’aspiration) |

| Plage de Te | −30 °C à −10 °C |

| Tension / fréquence | 220–240 V ~ 50 Hz, 1 Ph |

| Type de compresseur | Hermétique à piston (reciprocating) |

| Refroidissement compresseur | Statique |

| Domaine d’utilisation typique | Réfrigérateurs / congélateurs domestiques |

Enjeux pour le froid domestique

Les compresseurs GM70AZ et EGM70AZ s’inscrivent dans la stratégie industrielle de ZMC visant à fournir des compresseurs hermétiques compétitifs pour les fabricants de réfrigérateurs et les marchés de rechange. Grâce à leur compatibilité avec le R134a, ils restent courants dans les appareils existants, même si le secteur s’oriente progressivement vers des réfrigérants à plus faible GWP comme le R600a.

Pour les techniciens frigoristes, l’identification correcte du modèle et du gaz, comme on le voit clairement sur l’étiquette GM70AZ, est essentielle pour respecter les conditions de fonctionnement (tension, plage d’évaporation, type de détente capillaire) et garantir longévité et efficacité énergétique. Ce type de compresseur est largement utilisé dans les ateliers de service en Tunisie, en Égypte et dans la région MENA, où les pièces ZMC sont facilement disponibles.