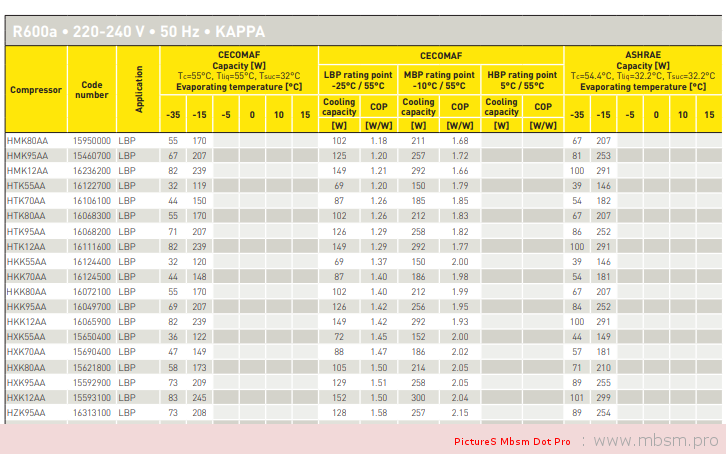

COMPRESSEUR ZEL , 200w ,HDL200A, R600a, LBP ,1/4 hp

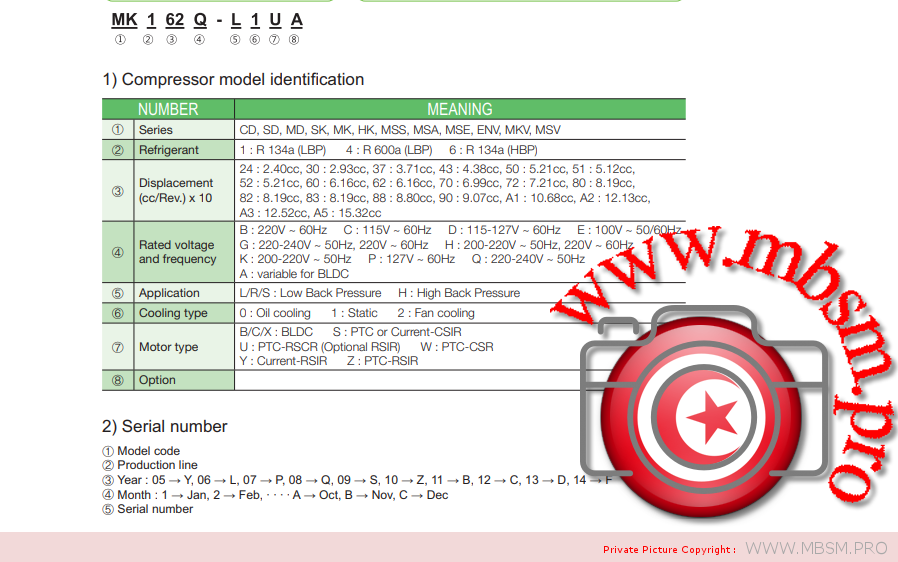

HP 1/5 HP Samsung SD162C-L1U2

2. Function Specifications Temp Range ℉ 32℉ ~ 40℉ Capacity Cubic Feet 7 Climate Class N Max Ambient Temp ℉ 89.6℉ Min Ambient Temp ℉ 59℉ Castors 5” 4EA Shelves 2EA Doors 1EA Exterior Finish Stainless Steel Inte …

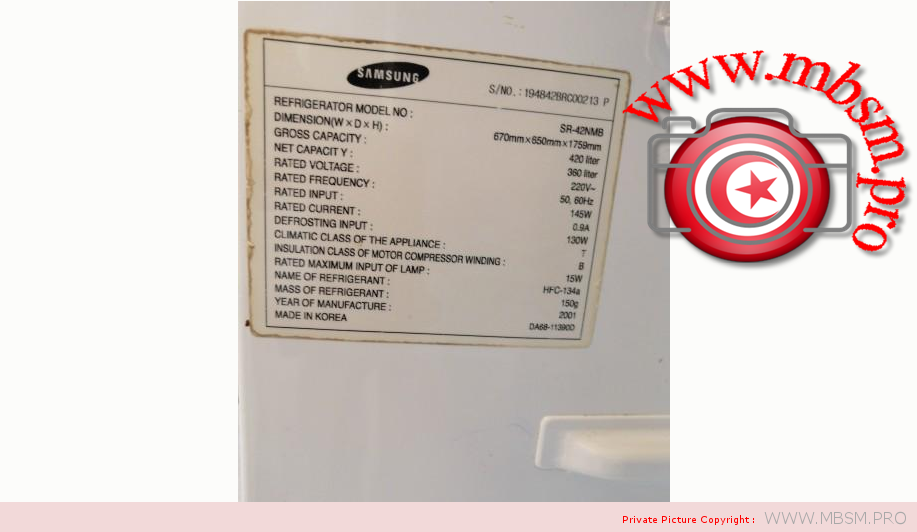

| Refrigerant: | R134a | |

| Discharge element: | C | |

| Cooling: | S | |

| Maximum ambient temperature [ºC]: | 43 |

| Cylinder capacity [cm³]: | 8,1 | |

| Displacement [m³/h]: | 1,4 | |

| Weight [kg]: | 10,6 | |

| Oil charge [cm³]: | 445 | |

| Oil type: | ISO VG 19 ESTER |

| Engine type: | RSIR | |

| Power [KM]: | 1/5 | |

| Starting element: | LST | |

| Power supply: | 220V 50Hz | |

| Voltage range: | 170-242 | |

| Locked rotor current [A]: | 18 | |

| Running winding resistance (25ºC) [Ω]: | 5,81 | |

| Starting winding resistance (25ºC) [Ω]: | 11,01 |

| Relays: | 3003 | |

| Shielding element: | MRP321LZ, T0683, AF11FI | |

| Starting capacitor volume [μF]: |

| milimeters | inches | ||

| Suction tube: | 6,5 | ||

| Service tube: | 6,5 | ||

| Discharge tube: | 4,9 |

Créez une clé USB démarrable de manière facile

![[rufus screenshot]](https://rufus.ie/pics/rufus_fr.png)

Rufus est un utilitaire permettant de formater et de créer des média USB démarrables, tels que clés USB, mémoire flash, etc.

Il est particulièrement utile pour les cas où :

En dépit de sa petite taille, Rufus fournit tout ce dont vous avez besoin !

Oh, et Rufus est rapide. Par exemple, il est environ deux fois plus rapide qu’UNetbootin, Universal USB Installer ou l’utilitaire Windows 7 USB, pour la création d’un média d’installation USB à partir d’une image ISO Windows 7. Il est aussi marginalement plus rapide pour la création de média USB démarrables Linux. (1)

Une liste non-exhaustive d’images ISO supportées par Rufus est fournie au bas de cette page. (2)

Dernière mise à jour 2019.09.16 :

| Bahasa Indonesia | , | Bahasa Malaysia | , | Български | , | Čeština | , | Dansk | , | Deutsch | , | Ελληνικά | , |

| English | , | Español | , | Français | , | Hrvatski | , | Italiano | , | Latviešu | , | Lietuvių | , | Magyar | , | Nederlands | , | Norsk | , |

| Polski | , | Português | , | Português do Brasil | , | Русский | , | Română | , | Slovensky | , | Slovenščina | , | Srpski | , |

| Suomi | , | Svenska | , | Tiếng Việt | , | Türkçe | , | Українська | , | 简体中文 | , | 正體中文 | , | 日本語 | , | 한국어 | , | ไทย | , |

| עברית | , | العربية | , | پارسی | . |

Windows 7 ou supérieur, 32 ou 64 bit. Une fois téléchargée, l’application est prête à être utilisée.

Je profite de cette occasion pour exprimer ma gratitude aux traducteurs qui permettent à Rufus, ainsi que cette page web, d’être traduits dans plusieurs langues. Si vous pouvez désormais utiliser Rufus dans votre langage, c’est eux qu’il faut remercier !

Téléchargez le fichier exécutable et lancez-le – aucune installation n’est nécessaire.

Le fichier exécutable est signé de manière digitale, et la signature doit indiquer :

Si vous créez un disque démarrable USB avec un clavier non-US, Rufus essaie de sélectionner une disposition de clavier qui correspond à la langue de votre système. Dans ce cas, FreeDOS, qui est la sélection par défaut, est recommandé vis-à-vis de MS-DOS, car il supporte plus de dispositions internationales de clavier.

Toutes les versions de Rufus, depuis la version 1.1.0, permettent la création d’un média USB démarrable à partir d’une image ISO (.iso).

Si vous n’avez pas de fichier ISO, la création d’une telle image, à partir d’un disque optique ou depuis un ensemble de fichier, est facile à effectuer. Vous pouvez juste utilisez l’une des nombreuses applications gratuites de gravure CD ou DVD, telles que CDBurnerXP ou ImgBurn.

Un FAQ pour Rufus est disponible ICI (en Anglais).

Si vous voulez soumettre un commentaire, un bug ou encore effectuer une demande d’amélioration, veuillez utiliser le système de gestion d’incidents de github. Ou bien, vous pouvez aussi envoyer un e-mail.

GNU General Public License (GPL) version 3 ou ultérieure.

Vous êtes libres de distribuer, modifier ou encore vendre ce logiciel, tant que vous respectez la licence GPLv3.

Rufus est produit de manière 100% transparente, depuis son code source public, en utilisant un environnement MinGW32.

0xC0030057 errors when trying to create a persistent partitions on a non-FIXED driveext formatting support should still be considered EXPERIMENTAL at this stage.ext2/ext3 formattingSi vous êtes développeur, vous êtes cordialement invité à modifier Rufus et soumettre un patch.

Etant donné qu’on me pose régulièrement la question, vous constaterez qu’il n’y a pas de bouton de donation sur cette page.

La raison principale est que j’estime que le système de dons n’aide pas vraiment le dévelopement logiciel et pire, peut être culpabilisant pour les utilisateurs qui choisissent de ne pas donner.

Si vous insistez vraiment, vous pouvez toujours effectuer une donation à la Free Software Foundation (FSF), puisque c’est la principale cause qui permet à des logiciels tels que Rufus d’exister.

Dans tous le cas, je profite de cette opportunité pour vous remercier de vos encouragements et surtout de votre enthousiasme vis-à-vis de ce petit programme : Cela reste très apprécié !

Mais s’il vous plait, veuillez continuer à utiliser Rufus sans vous sentir coupable de ne pas participer financièrement – vous ne devriez jamais avoir besoin de le faire !

Les tests suivants ont été conduits depuis une machine Windows 7 x64 Core 2 duo avec 4Go de RAM, en utilisant un contrôleur USB 3.0 ainsi qu’un périphérique flash 16 Go USB 3.0 ADATA S102.

| • | Windows 7 x64 | : | en_windows_7_ultimate_with_sp1_x64_dvd_618240.iso |

| Windows 7 USB/DVD Download Tool v1.0.30 | 00:08:10 |

| Universal USB Installer v1.8.7.5 | 00:07:10 |

| UNetbootin v1.1.1.1 | 00:06:20 |

| RMPrepUSB v2.1.638 | 00:04:10 |

| WiNToBootic v1.2 | 00:03:35 |

| Rufus v1.1.1 | 00:03:25 |

| • | Ubuntu 11.10 x86 | : | ubuntu-11.10-desktop-i386.iso |

| UNetbootin v1.1.1.1 | 00:01:45 |

| RMPrepUSB v2.1.638 | 00:01:35 |

| Universal USB Installer v1.8.7.5 | 00:01:20 |

| Rufus v1.1.1 | 00:01:15 |

| • | Slackware 13.37 x86 | : | slackware-13.37-install-dvd.iso |

| UNetbootin v1.1.1.1 | 01:00:00+ |

| Universal USB Installer v1.8.7.5 | 00:24:35 |

| RMPrepUSB v2.1.638 | 00:22:45 |

| Rufus v1.1.1 | 00:20:15 |

| Arch Linux | , | Archbang | , | BartPE/pebuilder | , | CentOS | , | Damn Small Linux | , | Debian | , | Fedora | , | FreeDOS | , |

| ReactOS | , | Red Hat | , | rEFInd | , | Slackware | , | Super Grub2 Disk | , | Tails | , | Trinity Rescue Kit | , | Ubuntu | , |

تم إضافة أقسام وكتب جديدة إلى مكتبتي على درايف

يبلغ الآن عدد الكتب لدي أكثر من 500 كتاب يمكنكم تحميل ما تشاؤون منها

بمجرد الضغط على الرابط سوف ينقلكم مباشرةً إلى الكتاب

https://drive.google.com/folderview…

كما يمكنكم تحميل الكتب عن طريق قناة التلكرام من خلال هذا الرابط

https://t.me/ThurayaElectronics

ملاحظة : ( تحزير إلى أصحاب النفوس الضعيفة ممن يريدون استغلال رابط مكتبتي على درايف لكي يقومون بتقصيره واستبداله بروابط مشبوهة أريد أن أقول لكم أنني أقوم بنقل الكتب وتغيري رابط الوصول إليها بشكل مستمر لذالك لن تنجح بهذا الأمر )

www.mbsm.pro , 500 Livres Documentaire.jpg (44 KB)

paramètres techniques

numéro de pièce

605185

fréon

R134a

type

GL90AA

voltage

220-240 V

fréquence

50 Hz

domaine d’utilisation

LBP

poids

9.4 kg

puissance

1/4 HP

puissance absorbée

184 W

cylindrée

8.1 cm³

système de moteur

RSIR

hauteur

185.6 mm

puissance à -30°C

148 W

puissance à -25°C

200 W

puissance à -20°C

261 W

puissance à -15°C

330 W

puissance à -10°C

407 W

puissance à -5°C

– W

puissance à 0°C

– W

puissance à +5°C

– W

puissance à +10°C

– W

température ambiante max.

43 °C

www.mbsm.pro-Cubigel-14H-GL90AA.jpg (52 KB)

غلق بمشبك قابل للطي ، مما يسمح لستة أقفال لقفل جهاز واحد.

أو القفل والعلامة هو إجراء أمان يستخدم في إعدادات الصناعة والبحث للتأكد من أن الآلات الخطرة مغلقة بشكل صحيح ولا يمكن تشغيلها مرة أخرى قبل الانتهاء من أعمال الصيانة أو الإصلاح. يتطلب الأمر عزل ” مصادر الطاقة الخطرة وجعلها غير صالحة للعمل” قبل بدء العمل في المعدات المعنية. يتم بعد ذلك قفل مصادر الطاقة المعزولة ووضع علامة على القفل تحدد العامل الذي وضعه. عندها يمسك العامل بمفتاح القفل ، مما يضمن أنه فقط هو أو هي قادر على إزالة القفل وبدء تشغيل الجهاز. هذا يمنع بدء التشغيل العرضي لجهاز ما عندما يكون في حالة خطرة أو عندما يكون العامل على اتصال مباشر به. [1]

يستخدم Lockout-tagout في مختلف الصناعات كوسيلة آمنة للعمل على المعدات الخطرة ويفوضه القانون في بعض البلدان.

EMBRACO is a company specialized in cooling solutions and

world leader in the hermetic compressor market. Our mission:

provide innovative solutions for a better quality of life, always

attentive to technological excellence and sustainability.

Technological leadership, operational excellence and sustainability are some of the pillars

which ensure the EMBRACO differential over other companies in the world market. Its

products are now considered the favorite leading home appliance manufacturers by major

automakers and are spotlighted by manufacturers of commercial refrigeration equipment.

With global operations and production capacity exceeding 34 million units a year, the

company offers solutions that are differentiated for their innovation and low energy

consumption. Its 11.500 employees work in factories and offices located in Brazil

(headquarters), China, Italy, Slovakia, Mexico, the United States and Russia.

Energy efficiency is constantly sought in the processes, products and relationships with

the communities where it operates. Our company is the absolute leader in this segment,

being able to offer products that meet the most restrictive international standards

regarding energy consumption.

As a worldwide leader, EMBRACO tries to anticipate market changes, and in doing so, our

company is in a state of permanent transformation. We continuously assess our processes

in order to maintain our leadership within the industry and promote growth, without

forgetting the pillars of our organization.

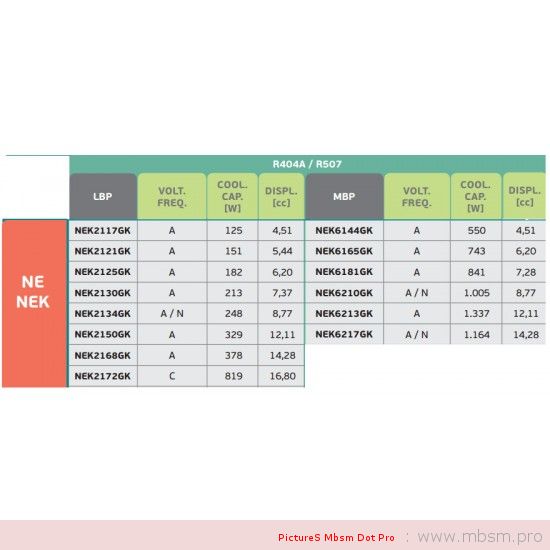

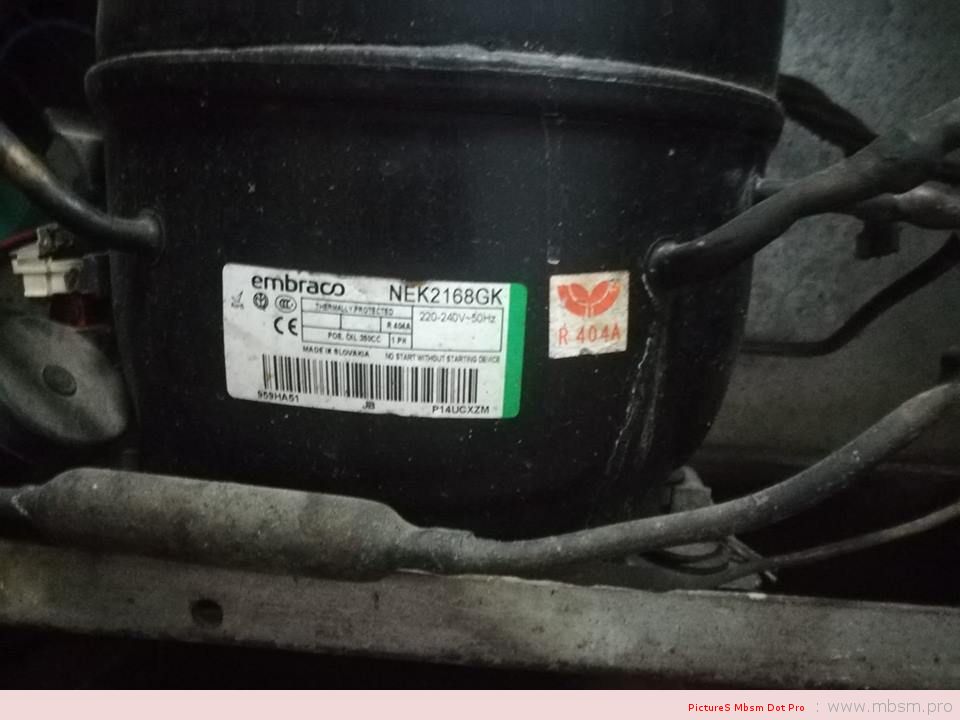

Compressor ASPERA NEK2168GK | NEK 2168 GK

| Refigerant | R404/R507 |

| Working range[stC] LBP | -40 to -10 |

| Nominal capacity [W] (evaporating temperature -23,3C, Condensing temperatur +54,4C) | 688 |

| Power supply | 220-240V 50Hz |

| Engine type | CSIR |

| Displacement [cm³] | 14,28 |

| Weight [kg] | 11,6 |

Evaporating temperature +55 C

| Evaporating Temperature | Cooling Capacity +/-5% | Power Consumption +/-5% | Current Consumption +/-5% | Gas Flow Rate +/-5% | Efficiency +/-7% | |||

| °C | (kcal/h) | (W) | (Btu/h) | (W) | (A) | (kg/h) | (kcal/Wh) | (W/W) |

| -40 | 226 | 263 | 897 | 370 | 3,46 | 6,01 | 0,61 | 0,71 |

| -35 | 309 | 359 | 1.224 | 435 | 3,57 | 8,22 | 0,71 | 0,82 |

| -30 | 413 | 481 | 1.640 | 506 | 3,73 | 11,06 | 0,82 | 0,95 |

| -25 | 541 | 629 | 2.146 | 584 | 3,95 | 14,52 | 0,93 | 1,08 |

| -20 | 691 | 803 | 2.740 | 668 | 4,21 | 18,64 | 1,03 | 1,20 |

| -15 | 863 | 1.004 | 3.424 | 759 | 4,53 | 23,43 | 1,14 | 1,32 |

| -10 | 1.058 | 1.230 | 4.197 | 856 | 4,90 | 28,92 | 1,24 | 1,44 |

| Refrigerant: | R404A, R507 |

mbsm.pro , Compresseur Aspera , Embraco NEK2168GK , R404A , LBP ,3/4 HP

Compresseur hermetique de Aspera – Embraco NEK2168GK – R404A

3/4 HP

220-240V 50 Hz

Cylindrée = 14.3 CM3

APPLICATIONS = LBP

Moteur type: CSR

A capacitor is a device used to store an electric charge, consisting of one or more pairs of conductors separated by an insulator.

Unexpectedly the electrolytic capacitors explodes with huge sound and sometime it smoke.

Get started , how to explode a capacitor ???

All capacitors have a maximum voltage and their destruction depends upon the internal construction. Explosions are understood only by delving into the internal construction of electrolytic capacitors – the primary culprit.

Most small value capacitors are simple sandwiches of conductor and insulator and when the voltage exceeds the dielectric strength of the insulation, they short out and burn, crack, pop, open, or smoke. Explosions are rare for these. Popping open is more likely. Their failure is self evident either visually or by failure to function in the circuit.

Most large value capacitors in order to be as small in physical size as possible, have to get the conductive plates of the capacitor as close together as possible and at the same time not so small that the voltage rating is impractical.

It is for this reason that the family of electrolytic capacitors was developed. The trick they use to get high capacity with small separations and reasonable voltage is that they use the “anodizing” of chemical electrolysis on one surface and a water based electrolyte for the other surface. Take one apart and see.

Notice that when a conductive metal is “anodized” by electrochemical process it turns into a dull film that is rather tough and is an insulator. This means that the actual conductive plate of the capacitor has this film entirely between itself and the other plate.

Then the other plate uses a trick too. There’s a water base solution soaked into a paper separator. Now if there was no water, the paper would be the dielectric of a normal capacitor separating the plates. But not here. Here the water has an alkali added to become a fair conductor. And as a liquid it soaks right into the surface structures of the capacitor. So it’s not the paper thickness at all – and not even the insulating surface on the other plate, but the inner recesses of the anodized surface that determine the dielectric distances.

So the operating voltage that a capacitor can tolerate depends upon how thick this anodized film is. And that is a function of it’s manufacture. Now there is a most useful characteristic that tells us we are nearing the max voltage, called leakage.

Here is a way you can check this out. Put in series, a test electrolytic capacitor (polarize it correctly), a variable power supply, a microammeter, and a 1 meg resistor (to limit and protect the meter). From zero as you increase the voltage there will be no current initially, then as you approach the spec op voltage, there will start a small leakage current. Since you have a limiting resistor here, you can increase the voltage without damage. continuing to increase the voltage discovers an increasing leakage current. It is a matter of practice how much safety you apply between the rating and the actual voltage of the circuit.

You can now see how it is that an electrolytic capacitor fails, it is not a voltage breakdown of the dielectric material, but the increase of leakage current that is troublesome. A rising leakage means heat which will boil the water and make steam – that’s the explosion process.

This is explosion as occasional failure of the few. But there is a more spectacular explosion process – it’s explosion by mistake – namely being installed backward. In such a case, the anodizing chemistry is reversed and rather rapidly, the anodized film starts to reverse, and quickly thins out at a weak spot in the rather large effective film area of the capacitor. Then we have short circuit currents and steam generation rather quickly. This sort of explosion usually fills the space (the casing or the whole room if exposed) with little shreads of aluminum foil and alkali soaked paper.

This insightful solution is most successful to achieve capacitors with large values in small spaces, but has a lot of lesser characteristics as the price to pay.

The worst limit, is storage. Electrolytic capacitors store very poorly, and the voltage rating can reduce substantially as the internal chemistry deteriorates. Some equipment manufacturers recommend that capacitors stored for a few years have their inner anodizing conditions restored by simply putting them to the spec voltage for a day to restore full spec.

At the least, if you replace capacitors with old stock, and it didn’t explode when power was restored, be aware that it may not reach it’s spec capacity value for a few hours. A capacitor in use will always be maintained by the voltage in the circuit you use it in.

When electrolytics are used without the circuit supplying a maintenance voltage to keep the anodized film that all depends upon, such as in speaker cross over applications that have no sustaining DC, then the values of the capacitor will deteriorate at least at storage rates, and if AC currents are substantial, even faster.

mbsm-dot-pro-capacitor-explodes- Pictures-A.jpg (4 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-A.jpg (1 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-B.jpg (3 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-B.jpg (1 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-C.jpg (3 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-C.jpg (1 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-D.jpg (3 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-D.jpg (1 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-F.jpg (2 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-F.jpg (748 KB)

mbsm-dot-pro-capacitor-explodes- Pictures-E.jpg (3 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-E.jpg (1 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-G.jpg (2 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-G.jpg (856 KB)

mbsm-dot-pro-capacitor-explodes- Pictures-H.jpg (2 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-H.jpg (690 KB)

mbsm-dot-pro-capacitor-explodes- Pictures-I.jpg (2 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-I.jpg (1 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-J.jpg (2 MB)